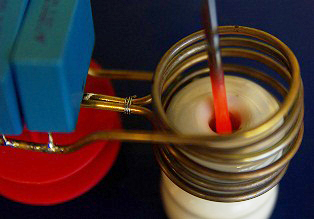

This great little project demonstrates the principles of high frequency magnetic induction and how to make an induction heater. The circuit is very simple to build and only uses a few common components. With the induction coil shown here the circuit draws about 5A from a 15V supply when a screwdriver tip is heated. It takes approximately 30 second for the tip of the screwdriver to become red hot!

The control circuit uses a method known as ZVS (zero voltage switching) to activate the transistors which allows for an efficient transfer of power. In the circuit you see here, the transistors barely get warm due to the ZVS method. Another great thing about this device is that it is a self resonant system and will automatically run at the resonant frequency of the attached coil and capacitor. If you want to save some time, we have an induction heater circuit available in our shop. You might still want to read this article though for some good tips on getting your system working well.

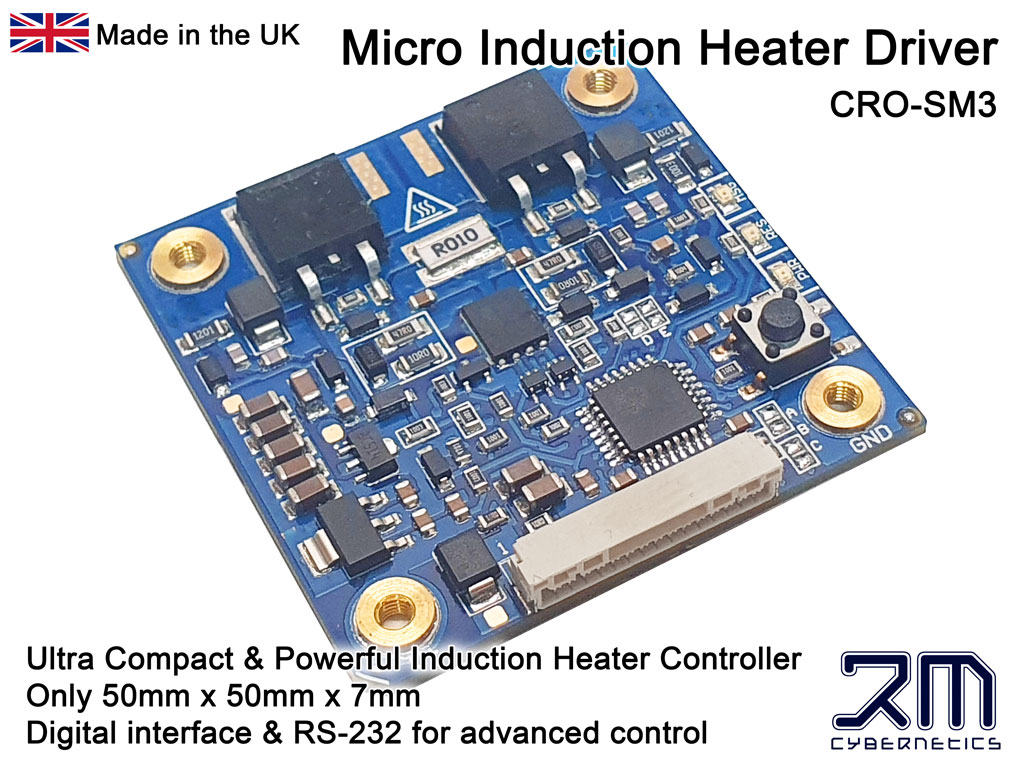

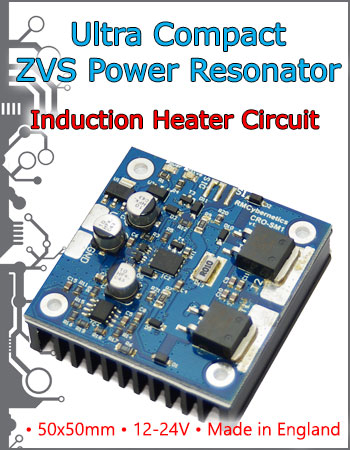

Induction Heater Circuit – CRO-SM3

Price range: $113.65 through $131.03

Select options

This product has multiple variants. The options may be chosen on the product page

Induction Heater Coil

$86.91

Select options

This product has multiple variants. The options may be chosen on the product page

How Does Induction Heating Work?

How Does Induction Heating Work?

When a magnetic field changes near a metal or other conductive object, a flow of current (known as an eddy current) will be induced in the material and will generate heat. The heat generated is proportional to the current squared multiplied by the resistance of the material. The effects of induction are used in transformers for converting voltages in all sorts of appliances. Most transformers have a metallic core and will therefore have eddy currents induced into them when in use. Transformer designers use different techniques to prevent this as the heating is just wasted energy. In this project we will directly make use of this heating effect and try to maximise the heating effect produced by the eddy currents.

If we apply a continuously changing current to a coil of wire, we will have a continuously changing magnetic field within it. At higher frequencies the induction effect is quite strong and will tend to concentrate on the surface of the material being heated due to the skin effect. Typical induction heaters use frequencies from 10kHz to 1MHz.

![]() DANGER: Very high temperatures can be generated with this device!

DANGER: Very high temperatures can be generated with this device!

The Circuit

The Circuit

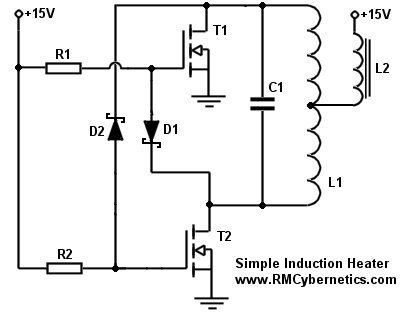

The circuit used is a type of collector resonance Royer oscillator which has the advantages of simplicity and self resonant operation. A very similar circuit is used in common inverter circuits used for powering fluorescent lighting such as LCD backlights. They drive a centre tapped transformer which steps up the voltage to around 800V for powering the lights. In this DIY induction heater circuit the transformer consists of the work coil and the object to be heated.

The main disadvantage of this circuit is that a centre tapped coil is needed which can be a little more tricky to wind than a common solenoid. The centre tapped coil is needed so that we can create an AC field from a single DC supply and just two N-type transistors. The centre of the coil is connected to the positive supply and then each end of the coil is alternately connected to ground by the transistors so that the current will flow back and forth in both directions.

The amount of current drawn from the supply will vary with the temperature and size of the object being heated.

From this schematic of the induction heater you can see how simple it really is. Just a few basic components are all that is needed for creating a working induction heater device.

From this schematic of the induction heater you can see how simple it really is. Just a few basic components are all that is needed for creating a working induction heater device.

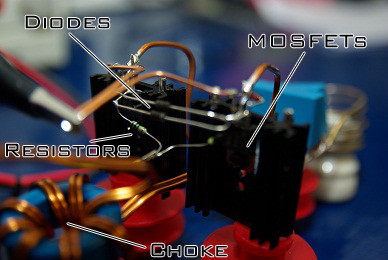

R1 and R2 are standard 240 ohm, 0.6W resistors. The value of these resistors will determine how quickly the MOSFETs can turn on, and should be a reasonably low value. They should not be too small though, as the resistor will be pulled to ground via the diode when the opposite transistor switches on.

The diodes D1 and D2 are used to discharge the MOSFET gates. They should be diodes with a low forward voltage drop so that the gate will be well discharged and the MOSFET fully off when the other is on. Schottky diodes such as the 1N5819 are recommended as they have low voltage drop and high speed. The voltage rating of the diodes must be sufficient to withstand the the voltage rise in the resonant circuit. In this project the voltage rose to as much as 70V.

The transistors T1 and T2 are 100V 35A MOSFETs (STP30NF10). They were mounted on heatsinks for this project, but they barely got warm when running at the power levels shown here. These MOSFETs were chosen due to having a low drain-source resistance and fast response times.

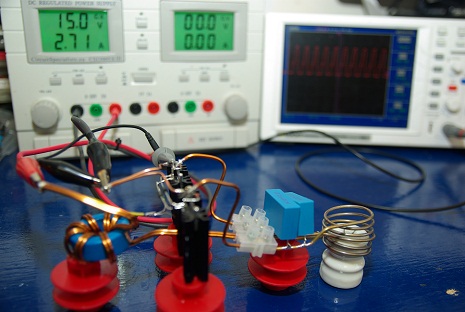

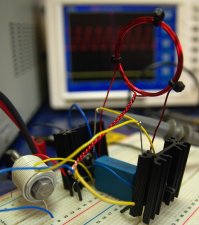

The inductor L2 is used as a choke for keeping the high frequency oscillations out of the power supply, and to limit current to acceptable levels. The value of inductance should be quite large (ours was about 2mH), but also must be made with thick enough wire for carrying all the supply current. If there is no choke used, or it has too little inductance, the circuit might fail to oscillate. The exact inductance value needed will vary with the PSU used and your coil setup. You may need to experiment before you get a good result. The one shown here was made by winding about 8 turns of 2mm thick magnet wire on a toroidal ferrite core. As an alternative you can simply wind wire onto a large bolt but you will need many more turns of wire to get the same inductance as from a toroidal ferrite core. You can see an example of this in the photo on the left. In the bottom left corner you can see a bolt wrapped with many turns of equipment wire. This setup on the breadboard was used at low power for testing. For more power it was necessary to use thicker wiring and to solder everything together.

The inductor L2 is used as a choke for keeping the high frequency oscillations out of the power supply, and to limit current to acceptable levels. The value of inductance should be quite large (ours was about 2mH), but also must be made with thick enough wire for carrying all the supply current. If there is no choke used, or it has too little inductance, the circuit might fail to oscillate. The exact inductance value needed will vary with the PSU used and your coil setup. You may need to experiment before you get a good result. The one shown here was made by winding about 8 turns of 2mm thick magnet wire on a toroidal ferrite core. As an alternative you can simply wind wire onto a large bolt but you will need many more turns of wire to get the same inductance as from a toroidal ferrite core. You can see an example of this in the photo on the left. In the bottom left corner you can see a bolt wrapped with many turns of equipment wire. This setup on the breadboard was used at low power for testing. For more power it was necessary to use thicker wiring and to solder everything together.

As there were so few components involved, we soldered all the connections directly and did not use a PCB. This was also useful for making the connections for the high current parts as thick wire could be directly soldered to the transistor terminals. In hindsight it might have been better to connect the induction coil by screwing it directly to the heatsinks on the MOSFETs. This is because the metal body of the transistors is also the collector terminal, and the heatsinks could help keep the coil cooler.

The capacitor C1 and inductor L1 form the resonant tank circuit of the induction heater. These must be able to withstand large currents and temperatures. We used some 330nF polypropylene capacitors. More detail on these components is shown below.

The Induction Coil and Capacitor

The Induction Coil and Capacitor

The coil must be made of thick wire or pipe as there will be large currents flowing in it. Copper pipe works well as the high frequency currents will mostly flow on the outer parts anyway. You can also pump cold water through the pipe to keep it cool.

A capacitor must be connected parallel to the work coil to create a resonant tank circuit. The combination of inductance and capacitance will have a specific resonant frequency at which the control circuit will automatically operate. The coil-capacitor combination used here resonated at around 200kHz.

It is important to use good quality capacitors that can withstand large currents and the heat dissipated within them otherwise they would soon fail and destroy your drive circuit. They must also be placed reasonably close to the work coil and using thick wire or pipe. Most of the current will be flowing between the coil and capacitor so this wire must be thickest. The wires linking to the circuit and power supply can be slightly thinner if desired.

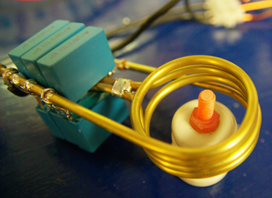

This coil here was made from 2mm diameter brass pipe. It was simple to wind and easy to solder to, but it would soon start to deform due to excess heating. The turns would then touch, shorting out and making it less effective. Since the control circuit stayed relatively cool during use, it seemed that this could be made to work at higher power levels but it would be necessary to use thicker pipe or to water cool it. Next the setup was improved to tolerate a higher power level…

Pushing it Further

Pushing it Further

The main limitation of the setup above was that the work coil would get very hot after a short time due to the large currents. In order to have larger currents for a longer time, we made another coil using thicker brass tubing so that water could be pumped through when it was running. The thicker pipe was harder to bend, especially at the centre tapping point. It was necessary to fill the pipe with fine sand before bending it as this prevents it from pinching at the sharp bends. It was then cleared out using compressed air.

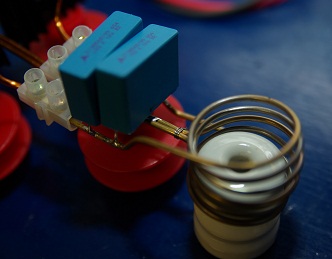

The induction coil was made in two halves as shown here. They were then soldered together and a small piece of pvc pipe was used to connect the central pipes so that water could flow through the whole coil.

The induction coil was made in two halves as shown here. They were then soldered together and a small piece of pvc pipe was used to connect the central pipes so that water could flow through the whole coil.

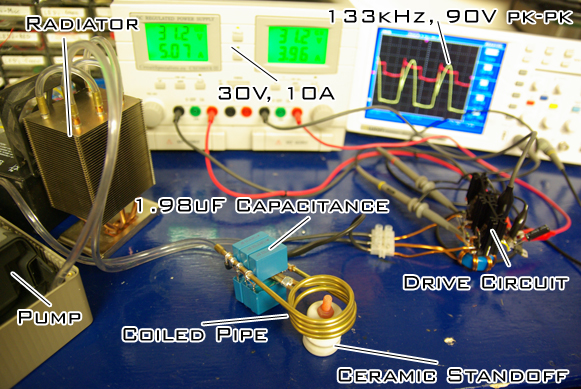

Less turns were used in this coil so that it would have a lower impedance and therefore sustain higher currents. The capacitance was also increased so that the resonant frequency would be lower. A total of six 330nF capacitors were used to give a total capacitance of 1.98uF.

The cables connecting to the coil were just soldered onto the pipe near the ends, just leaving room for fitting some PVC pipe.

The cables connecting to the coil were just soldered onto the pipe near the ends, just leaving room for fitting some PVC pipe.

It is possible to cool this coil simply by feeding water through directly from the tap but it is better to use a pump and radiator to remove the heat. For this, an old fish tank pump was placed in a box of water and a pipe fitted the outlet nozzle. This pipe fed to a modified computer CPU cooler which used three heat-pipes to move the heat.

The cooler was converted into a radiator by cutting the ends off the heat pipes and then linking them with PCV pipes to the the water would flow through all 3 heatpipes before exiting and going back to the pump.

If you do cut some heatpipes yourself, make sure to do it in a well ventilated area, and not indoors as they contain volatile solvents that can be toxic to breathe. You should also wear protective gloves to prevent skin contact.

This modified CPU cooler was very effective as a radiator and allowed the water to remain quite cool.

This modified CPU cooler was very effective as a radiator and allowed the water to remain quite cool.

Other modifications needed were to replace the the diodes D1 and D2 with ones rated for higher voltages. We used the common 1N4007 diodes. This was because with the increased current there was a larger voltage rise in the resonant circuit. You can see in the image here that the peak voltage was 90V (yellow scope trace) which is also very close to the 100V rating of the transistors.

The PSU used was set to 30V so it was also necessary to feed the voltage to the transistor gates via a 12V voltage regulator. When no metal was inside the work coil, it would draw about 7A from the supply. When the bolt in the photo was added, this went up to 10A and then gradually dropped again as it heated up beyond curie temperature. It would certainly go over 10A with larger objects, but the PSU used has a 10A limit. You can find a suitable a 24V, 15A PSU in our online shop.

The bolt you can see glowing red hot in the photo took about 30 seconds to reach maximum temperature. The screwdriver in the first image could now be heated red hot in about 5 seconds.

In order to go to higher power than this, it would be necessary to use different capacitors or a larger array of them so that the current was more distributed between them. This is because the large currents flowing and high frequencies used would heat the capacitors significantly. After about 5 minutes of use at this power level the DIY induction heater needed to be switched off so that they could cool down. It would also be necessary to use a different pair of transistors so that they could withstand the larger voltage rises.

In all this project was quite satisfying as it produced a good result from just a simple and inexpensive circuit. As it is, it could be useful for hardening steel, or for soldering small parts. If you decide to make your own induction heater project, please post your photos below. Please read through the other comments before making your own as it could save you time later on.

If you wish to simulate this project for testing different inductance values or transistor choices, please download LTSpice and run this DIY Induction Heater Simulation (Right click, Save as)

How hot will it get?

It is difficult to say how hot you will be able to get something as there are many parameters to consider. Different materials will react differently to induction heating and their shape and size will affect how the heat up or shed heat to the atmosphere.

You can get a rough idea using some basic calculations with the formula below, or if you prefer, we made a handy Heater Power Calculator that can work it out for you. This form includes materials (like water) that can not be directly heating using induction heaters, but it is still useful if you are trying to work out for example the power needed for heating a pan of water using a induction heater.

How hot will something get?

How long will it take for something to reach a specific temperature?

How much heater power is needed to heat something to a certain temperature?

EXAMPLE: How hot will 20g of Steel get in 30 seconds when heated with a 300W heater? (assuming 100W is lost to the surroundings)

Formulae:

Q = m x Cp x ΔT

ΔT = Q ÷ m ÷ Cp

Working:

(300W – 100W) x 30s = 6000J

6000J ÷ 20g ÷ 0.466J/g°C = 643.78°C

Result:

20g of Steel will increase in temperature by 643.78°C when heated with a 300W heater for 30 second(s).

Troubleshooting

If you have trouble getting this working, here are a few tips to help troubleshoot your home made induction heater project….

PSU (Power Supply)

If your PSU is unable to deliver a large surge of current when the induction heater is powered on, then it will fail to oscillate. The voltage from the supply will drop during that moment (although the PSU may not display this) and this will prevent the transistors from switching correctly. To help with this problem, you can place several large electrolytic capacitors in parallel with the supply. When charged they will be able to deliver a large surge current to your circuit. A good powerful supply would be our 24V 15A DC PSU.

Choke (inductor L2)

This limits the power to your induction heater. If yours is not oscillating, then you may need more inductance to prevent voltage drop in your PSU. You will need to experiment with how much inductance you need. Better to have too much, than too little as this will only limit the power of the heater. Too little may mean it wont work at all. If your inductor core is too small, high current will saturate it and cause too much current to flow and potentially damage your circuit.

Wiring

Keep the connecting wires short to reduce stray inductance and interference. Long wires add unwanted resistance and inductance to the circuit and can result in unwanted oscillations or poor performance. Our 30A power cable is well suited to this.

Components

The transistors chosen must have a low voltage drop / on-state resistance otherwise they will overheat, or even prevent the system from oscillating. IGBTs will proabbaly not work, but most MOSFETs with similar ratings should be OK. The capacitors must have a low ESR (resistance) and ESL (inductance) so they can tolerate the high current and temperatures. The diodes should also have a low forward voltage drop so that the transistors switch off correctly. They should also be fast enough to work at the resonant frequency of your induction heater.

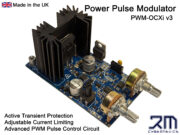

Powering it up

When switching it on, do not have metal within the heating coil. This can lead to larger current surges which could prevent the oscillation from starting as mentioned above. Also do not try to heat large amounts of metal. This project is only suitable for small induction heaters. If you want to control or gradually turn up the power, you can use one of our power pulse modulator circuits. See post 5108 below for details.

Brain

You will need a brain that functions reasonably well to make this project safely. It can be very dangerous to build an induction heater, so if you are new to electronics, you should get someone to help you make it. Approach things logically; If it is not working, check the components used are not faulty, check connections are correct, read this whole article and all the comments, search Google if you do not understand any of the terms, or read through our Learn Electronics section. Remember: Hot things will burn you and can set things on fire; Electricity can electrocute you and also cause fire. Put safety first.

Induction Heater Circuit available to buy

Induction Heater Circuit available to buy

A fully assembled and tested Induction heater circuit is now available to buy from our shop. This circuit is a compact and efficient version of the circuit in this article.

The circuit has in input for enable/disable of the power output so that it can be modulated by a PWM circuit for power control.

You can also buy the induction coil or parts such as copper pipe, litz wire, water cooling, capactiors, 24V PSU and more.

I have a cheap induction heater that has a knob for “output current” is this referring to the current in the coil or in the workpiece itself?

I think you need to ask the company that makes/sells it, or refer to the manual.

Hi,

I have created a circuit using the CRO-SM2, the coil kit with 4 turns coil about 45 mm diameter, Oled display and 5A Choke. I am heating a 10 mm rod, lenght 100 mm. The circuit works fine, but I would like to reduce the heating power significantly. Now I would need to switch the circuit on for less than a few percent of the time to heat the rod to a constant temperature between approx. 80 deg.C. Could you advise me how to achieve this. Does the L2 copper coil need more turns?

Thanks,

G.J. Scheers

Hello. The best way to control heating power is by adjusting the voltage supply to the choke. The cuicuit needs 12V, but you can use a seperate supply for the heating coil (they must share a common GND). One way is to use a DC-DC convertor to step the voltage down if you do not have a suitable PSU.

More turns MAY reduce heating, but it depends on magnetic coupling to the workpiece which may even increase the heating effect.

Hi would it be possible to use a bifilar coil to

to dissipate the current and give a lower heat

generation in the coil?.thanks

Hello, the project is very interesting so I built guiding me in his scheme to try. I have done some tests and after 5 minutes of continuous work the consumption current in the load decreases. I think it’s because the resonant tank gets too hot and change its characteristics or physical properties.

I wonder if the induction heater can operate for several hours without losing their efficiency , thanks.

Hi is it posible to build an induction heater at larger scale I need to heat up a metal plate about 3/16 thick by 8 feet wide by 22 feet long? If yes would you be able to design it and post it here? Thank you for your help

I am trying to build this circuit for a high school science project and can use a little help. To keep it simple I bought The CRO-SM1 Heater Driver Circuit, the 24V 15A DC PSU, and the prebuilt Induction Heater Coil (CT-400), water pump, and choke coil from an old microwave (picture attached). Basically everything in Figure 3 of the CRO-SM1 manual.

I have gotten to the point where I have everything connected pump working, etc. and when I initially turn the switch on at the switch the power and active LED’s come on initially. However when I connect the choke to the power supply the LED’s turn off within a half second.

I went through the CRO-SM1 documentation and shortened the connection to the work coil to 4cm (12guage wire) thinking that was the problem but have the same results. My only unknown is the choke coil but I don’t have an inductance meter but find it hard to believe that is the problem.

Do you have any suggestions?

I built my circuit twice.

The first time I used the IRF540N (similar to stp30nf10), five capacitors of 470 nF (totaling 2.35uF), two diodes 1N4007, two resistors of 220ohms, an inductor of 2.3mH. The circuit one heated and worked screwdriver for about 3 minutes at a voltage of 8V and 4A current, but the capacitors burned.

I did the exchange of ALL the components, but I used MOSFETS FQP33N10 (like also with STP30NF10) and twelve capacitor 470nF (totaling 5.64uF) to support higher currents. But the circuit does not work, the MOSFETS heat up and is apparently toggling, but there is no temperature increase in capacitors and or the key used in the work coil.

What should I do? The problem may be attached to the resonant frequency?

Thank you!

photo1: 1° circuit

photo2: 2° circuit

photo3: drive

Is it possible to use this concept to heat a 44 quart stock pot? It will be used in soap and lotion production.

I need to design and build a very small, portable induction heater. the best way to describe my final application is that it is similiar to building an induction based portable hot glue gun…. the object i need to heat (not melt) is about the diameter of a pencil. i need the speed, accuracy, efficiency of induction heating over resistive heating. the end product needs to be able to be packaged in something the size of a hot glue gun. can anyone point me in the right direction to get on the right track quicker than pure experimentation on my part would allow? i am an are engineer but have a weak knowledge of electrical engineering – that’s why i have come to the experts… any help would be greatly appreciated.

dennis

Thanks for the project, RMCybernetics!

I made the induction heater and it works very well, but I did make one change. Instead of using tubing as my induction coil, I made a Litz wire of 24 strands of 30 gauge magnet wire, then wound that into 3 concentric rings of coiling equaling 21 windings. This has dramatically increased the efficiency of heating as well as preventing heat generation in the coil. I can run it for several minutes without the coil itself getting too hot. If I needed to run it longer, I’d increase the number of strands in the Litz wire, which I may actually end up doing, anyway.

Thanks again!

i use power supply 24v 7.5a,it burn capacitor but i use it 0.33 uf x2.power supply affect capacitor?

i use powersupply 15v 4.5a ,capacitors 0.33 uf x2 and choke coil 12 turn resistor 240omh 1w mosfet p30nf10.What should I do to make things hot 300deg C.and i change mosfet irf540 ,will affect to circuit?

Hi, a friend send me this page because he followed your schematic to get his engineer degree so I try to do something like this to get my degree but I’m a Mechanical Engineer so I don’t have much knowledge about electricity and electronic and I have some doubts than I hope you can help me.

Already I do this circuit and it’s works pretty good, I put a nail and get 600°C easily, i Have 29 capacitor (0.33uF 1200VDC), IRFP260 Mosfets, 30A 600V ultrafast diode and the coil (4 spirals, 5cm diameter and 5cm length) is cooled by water.

1) how can I desing a coil to works in high frecuency, I mean some equation because all I’ve seen is for low frecuency.

2)How can I know the frecuency work of the heater using a oscilloscope.

3) How can I get low frequencies to get more penetration depth.

thanks a lot!

What you are detailing is a lot like the 10Megawatt

furnaces we used at the steelmill to melt 10tons at shot of scrap.(The scale of things had us using plastic 3inch firehose with antifreeze instead of the copper tubing you was talking about in the article.)

With my steam hobby I am looking do about that many

pounds of metal for castings and parts.

Do you have anything with that much power..that I can build.

Sorry, but I can not really answer much more on this article as I think so many have been answered allready I am beginning to just repeat myself. Also I can not answer questions specific to each individual project as there is just too much to consider.

Regarding heat loss to surroundings it is actually a little complex as the hotter it gets the more it looses. At some point an equalibrium is reached and it stops increasing in temperature.

For many of the questions asked, the best way is to experiment with with the system and see some results directly. if you do, please post your results for others to learn from too.

Hi,

Firstly, excellent article!!! taught me so much!

I am very new to induction heating. I have no formal training in electronics, but I have a need to heat lots of rifle brass cases through induction.

Question 1: What is it about the CRO-1 that makes it self resonating with parallel LC circuits? My understanding is that you need to feed the power to the LC circuit in the correct Hz. Is the CRO-1 circuit the same as the DIY circuit?

Question 2: What is the ideal resonant frequency for rifle brass (70C/30Z)? It is imperative that one does not heat the whole rifle case (otherwise the soft brass can explode in the rifle breach), but just the neck, or bottled part of the neck of the case. Should I cut one of these off and weigh it to enter into your induction calculators?

Question 3: How do you measure heat lost to surroundings in W? Surely there are too many factors here to measure, and one just needs to estimate this? Would 150w seem sufficient?

Sorry for my questions, I am trying to learn as much as I can. Such a good resource for this kind of thing!

Thanks in advance.

Thank you for this great article!

I have built this circuit a few times, and almost every time it worked fine.

I would now like to make it more powerful!

I have a 40V 25A power supply (MOT + Rectifier + 20’000uF of filtering)

To drive the gates I have another supply, a 12V one.

It used to work like a charm until I turned on my 40V power supply before the 12V one…

I generally like fireworks, but not on my circuits 🙁

What kind of circuit protection would be possible to add to prevent this from happening again?

I noted that in some responses you mentioned PWM, an useful feature to have, but I didn’t get how you would add it to the circuit.

Thanks for your time and sorry for my English.

-Luca

I may be blind but where do I put the neutral. Also is a 24VDC 2.5A a proper power supply. I know the 24V will work but I dont think 2.5A will work.

M very thankful to you as i succeeded in doing the project. i am stuck with the simulation could you please help me out in finding output current ??

I have done model by giving 15v and load current is 0.55A as i could heat the rod by 170degC and now the question is, i needed to know how the changes occur in temperature by changing the values of choke, work coil and capacitor..

I have downloaded LTspice and tried to run your netlist as per mentioned in the previous comments but could fetch output..

I have tunned the tank circuit for 1MHz as per the above mentioned supply , it would really be helpful if you please respond me for finding the temperature, frequency and in simulation of the model..

I have done a model but not finding the proper results..

Hello, I tried building the circuit with some parts from mouser electronics, I have a 4 uh coil and a 10 ufd motor run capacitor rated at 400v. When everything is plugged in with 13.5 volts to the gates and 24 volts to the coil both of the MOSFETs get really hot and I don’t have enough time to check if snything in the coil is heating up before the mosfets start smoking. Is it possible that I’m not getting any oscillation and pass straight dc through both transistors and that I need a larger choke between my power supply (transformer+rectifier) and coil or is there some other issue i’m not thinking of. The MOSFETs are SUP50N10-21P made by vishay, the diodes (another possible issue?) are 625-1N4934GP-E3 mouser part number and rated at 200 ms recovery time so 5000 khz which should be enough and I’m using 220 ohm resistors. Any guidance in the right direction would be greatly appreciated.

For this induction heater, you are using a coil to heat up the part and the coil can be removed by pulling it up and out. If you were connection 2 pieces of tubing in a closed circuit, for example, how to get the coils out? Can you use a clam shell design and get the same results? I mean like a block of steeel, hole drilled then spit in 2 pieces with water pushed in and current around the hole and clamp it over the tubing? Does the heater have to be coils for the induction principle to work?

Does the coil used to heat the part, does that have to be a coil? I have seen clam shell type tools for induction heating also, ideal for welding as you can get in and out of what your welding up after its one piece. If, say, a block of steel slit in 1/2 with holes drilled for varous tubing sizes was made, (clam shell configuration), could it be used instead of a coil if both halves were clamped around the part to be heated? Could this solid stock set up the same induction as copper coils do, or would it have to be made like a transformer in pieces? Sorry, new to this technology, any info is appreciated

First question:

You said that you will

"post a new project in future which allows for higher power levels."

Did you made the project and if yes where is it?

Second q:

Knowing the characteristics of your circuit and power supply, is there a possibility to calculate approximatively the maximum temperature reached in for example a cube of 1cm3 of a metal like copper or iron?

@Sadek

I had exactly same problem because my RF Choke had fewer turns, then I used Choke with 35 turns and it worked fine.

Final remark, when I use a small choke inductor (as the picture), the PSU stops working after a few seconds of operation !

Here’s a picture of my PSU.

Would really appreciate any advice or just a hint. As I have no clus why the system is not oscillating and nothing gets hot in the working coil.

Thanks !

Hello RMcybernetics,

I tried to build your induction heater but with negative results. I read the troubleshooting section and the comments and think the problem might come from my PSU, a ATX power supply (modified to provide 12V 10A).

The Mosfet (IRF520N) gets really hot, really fast. I have tried different choke inductor. The one on the picture tend to heat up, as well.

With a yellow toroid (25-20/10), how many turns are required to get 1mH ?

I think the problem is either the choke inductor or the PSU.

Can you help ?

Thanks

Hi I think I have a problem with my circuit. Every time I connect it to power supply for 15V, i get overload in the system. Could you look at it please. I tried to take a clear picture. thanks

Can this center-tapped drive circuit be used to drive a levitating induction coil design. Sort of like this but with a center tap?

http://www.mindchallenger.com/inductionheater/inductionlevitation.html

I am currently constructing a smd pcb model of your circuit. I am interested in providing about 110w to a thin steel rod. Would 50V power mosfets be sufficient? I am also have trouble locating the choke that you use in your prebuilt induction circuit. Where can I find one to use on my board?

Your DIY Induction Heater looks super interesting.

I am trying to figure out how I would need to modify your circuit to make a low watt version of this.

For my upcoming project i need to heat a 5cmx5cm metal tile from underneath in order to make 5 ml of water boil away.

So the heater does not need to get hotter then 150˚C.

The second question is if i could avoid having to convert the main AC voltage to DC, just to turn it back in to high freq AC.

Could I right away some how use the mains AC?

i have made many AC dimming circuits before but have not dealt with induction until now.

thanks for any advice.

I would like to enquire, how can I use this heater directly on 230V AC? I need 2kW power. Have somebody some idea? Thanks in advance!

Will this be useful somehow in building up a food dehydrator?

Hi. i have a problem with the circuit. i have a power supply 15vcc in the inductor and another power supply for the 12v in the gate mosfet, the ground is in common. when i startup the sytem i see the wave in the drain fo the mosfet, but the frequency continous to increase and in 5 seconds one of the two mosfet go in short circuit. i have a capacitor of 1uf 275vac x2 for resonation. what is the error for your opinion?

thank you

Mike, there are a lot of variables involved which is all beyond the scope of this article so i can not help with your project.

Matthew, it may be easiest to simulate it by adjusting the parameters in the spice model in the article.

Hi RMcybernetics, I am currently looking to build a low power version of this heater (15v 0.5A). I’m aware that I will not see anything close to the results of the original. I saw that you mentioned that the work coil length and choke length are the variables that limit the current. Is there any practical way to determine the coil size I would need other than trial and error? Ant help would be appreciated

As part of my on-going studies could I use this circuit ( more realistically your module )to drive a larger, multi-turn coil (air gap transformer?) to build a demonstrator for Inductive Power Transfer of around 1kW?

If so, what do I need to be ‘wary’ of in terms of the coil specification/design & also, what is the upper DC voltage limit for the current components?

Thank you in advance.

thank you. i forget to tell you that i use mosfet IRF640N, they have VDSS 200V and Id current 18A.

I think they don’t destoryed mosfet

confim me thank you

No, the MOSFETs would be destroyed. If you want to disable the output temporarily, connect the gate terminals to ground.

if i use the original schematic can I have a 70VDC power supply or i must make some modify?

i Try at 30VDC and it is ok, but i always have a compsumation of 2A at the secondary of the trasformer, can i eliminate the hing compsumation at standby?

Do not use a battery charger. You need a proper power supply. It seems like the battery charger has overcurrent protection and is cutting out.

Hello….My circuit is doing something without blowing any parts so I think it’s hooked up correctly……I’ve got a 3/4inch dia work coil (12 turns #12 wire, centertapped), a 5uf 400 V cap, and my choke is 6 turns of #12 wire on an OD 1.5in., ID 3/4in, 1/2in wide white ceramic donut…..My power supply is a car battery charger with 6v/10A, 12V/2A, and 12V/10A outputs….Here is what is happening….When I turn on the power with any of the V/Aranges, at a specific time interval for each power range, the meter on the charger will spike to 12V, hold for a certain amount of time and then drop back to zero….When it spikes, it energizes the working coil (you can hear and feel it) then the power source drops back to zero (I can hear what sounds like a breaker trip within the battery charger) then after a about 10 seconds it powers the circuit once again….I’d appreciate some pointers…..Since I haven’t fried any parts, I think I can begin trying different chokes…What I am not sure about is if my combination of parts is not allowing oscillation or if my supply is not adequate….I hope to hear from you and have the very best of the holiday season…..Dennis

Hello…Your patience with questions is well appreciated…I need to go from Rockwell harness 40+ to 60+ to harden the flat edge of knives used to cut paper receipts…The material is 21 gauge tempered steel (90mm x 8mm)… I haven’t tackled the math involded yet nor read all of the thread so your patience is greatly appreciated….I have a 6/12V, 210 amp swithcable car battery charger on hand…Good enough? and if so should I eliminate the rectifying components?…..Second, my working coil needs to be 90+mm long and about 5/8-3/4 diameter for the piece to enter completely…..I have a roll of 14 gauge wire…Would I be better off using the recommended 12 gauge?…..I realize that very soon I’m going to have to take a look at the math and try to figure out how and why this set up works. Any pointers from what I’ve described…Thanks….Dennis

i want to make this circuit as battery operated one. If possible send the details pls….The temperature range of 400 C is good for me..

I could not suggest why it does not work. You are right about the PSUshowing a short indicating no oscilation.

Induction hobs use a higher voltage on the coil so they can output more power without getting as hot. Heat loss in the coil (ignoring eddy losses) is proportional to current times current times resistance. As Power = Volts times Amps, using higher voltage means you can have the same power, with less current. Less current mean less losses. This is why power lines distribute electricity at high voltages.

Just waiting for a HV scope probe before I start on mark3!

Howvere been thinking; Why do our coils run so hot when the domestic cooking version doesn’t and these are rated at 2 kW?

Thanks for the reply. Problem I have at the moment is that it doesn’t resonate initially. With 12v regulated it shows a short cicuit and so PSU limits the current (to me this implies no resonnance) If I momentarily disconnect the feed to the inductor then it resonnates!

Any ideas please?

Hammad, No.

Will, Look at the diagram in the comments. It shows a 12V regulator used for the gate drive voltage.

Ahmad, you need to cool your transistors better. Use much larger heatsinks.

Hi again,

After a bit of reading and thinking about it I realised how I fried my STP30NF10s:

The max Gate-Source voltage is stated as 20 v. I probably at one time applied 32 volys. What we need to know is that there are 2 posible power supplies needed:

1. A regulated or pwm’d gate driver supply – minimum current

2. The heater coil driver PSU which can be much bigger (like 30v at 30 amps)

Or as you say use a 16 volt zenner across Gate-Source to limit the gate voltage to the zenner voltage. (Cathode to gate, anode to source)

Thank you RM

I’ve read most of the comments

I use the battery 12V 33A

I Used IRFP250N 200V 30A 214W 0.075Ohm AND 4 Capacitors 330n 2000V + 2 Capacitors 100m 2000V AND 7812 and 2 zener(between gate and source )

But mosfets still heated, I burned 6 Mosfet

i tried 3 different choke

I tried 3 different inductor for L1

the Screw will become red hot after 30s and mosfet damaged after 50s and when i use a larger metal the mosfet damaged after 20s

the circuit take about 4A and 10A When load

I measured voltage Between the two sides of L1 and was 40V

can you help me?

can you tell me how i can reduce or Increase the voltage on L1?

Thank you

Hi RMC. Many thanks for all the work you put this project.

I built to your spec but using the 4007 diodes. Powered from a 30v 3Amp max bench supply. Things started to warm up but then supply tripped back to 5v and showed a dead short. Checked the mosfets and they were fried. How can the above supply fry 35 amp 100 v mosfets?

if the inductance of L2 (choke) is decreased then power of heater would be reduced?

clement, As long as your PWM is pulling them low to disable them, then floating when high so they can continue to resonate.

Hammad, Yes I have seen it work like this, but I found it was a bit more fussy about the coils I attatched. Please post your results if you take this approach.

can i use two chokes each at darains of Mosfet 1 and 2 to use coil without centre tape.

I want to use this circuit in Wireless power transfer. My primary coil is not centre-taped, so is there any way i could mange to modify this circuit?

Will 2 separate chokes at each drain terminal work?

HI,

I’m looking for a low power induction heater (about 30 to 40w) And after a couple hours of reading, studying, and simulating, I have found that the best option for me was to use your self resonating power oscillator applying a 100kHz PWM (rate 70%off/30%on) on the resisor R1 et R2 (gate of the mosfets)

Its showing good results with LT SPICE, my question is : will it work in real life ?

Thanks in advance

Clement

You right, it seems 1N4007 has 30us TRR, so it is suitable for frequencies less than 33khz… I’m going to try 1N5819 due to its very low TRR ( less than 10ns)… Thanks.

The 1n4007 is not very fast so this is probably the problem. Use a faster diode.

My diodes becoming too warm and the input current becoming low, what’s the problem? I’ve use 1N4007 and IRF3710.

Thanks

Graham, Yes it can heat things to that temp.

chan, I do not have this information.

What is a typical efficiency for this circuit (ie. percentage of input power that goes to heating the work piece)? Also, any tips for improving efficiency other than reducing the distance between the work piece and the coil and using a work piece that is ferrous

Hi, i’m interested in this device to seal optical fibres into a stainless steel (316L) component. My process requires a melting point of around 350 degrees C. Is you device able to generate this kind of temperature?

I’d possibly like to purchase an off the shelf kit, of induction board, coil, PS, cooling system etc….

Dear sir,

Recently I have built this circuit and it works pretty well, but I want more power output ( about 500w)! at first, is it possible? secondly, if yes, how? I have used IRF3710.

curious if I would be able to use a computers power supply?

and also would it be possible to have the parts list sent to me? via comment/email??..

thanks

You would need to show us how you have it all connected.

Hi RMC

I now am running my heater circuit successfully from a couple of car batteries in series – 24 volts available max via a PSU circuit. No load DC current is about 6 amps, rising when metal workpieces are inserted into the coil.All nice & predictable.

I have a workpiece loader/unloader fitted & use timer modules to switch on the oscillator & then to insert the workpiece into the coil to heat it automatically.

I have a problem when running at high power, The timer modules seem to be influenced somehow and my time delays are affected – I suspect high frequency interference on the DC power lines – Is this likely & how would I be able to filter this out of the timer circuits?

Yep, that is all normal.

I build the circuit using IRLZ 44N MOSFETS. The coil is made of 1.7mm copper wire (6 turns with a diameter of 25mm). For the caps i use 2 x Vishay BFC233922334 wich makes 660nF total. The gate resistors are 270 Ohm ones. The circuit oscillates stable at 250khz, which is fine. But everything gets relatively hot. the coil, the caps and the FETs get at least so hot, that i can barely touch them. i understand that the coil gets hot. but the FETs should not get hot, do they? And what about the caps? they should not get to hot either, i think?!

thanks in advance

ps. im driving the circuit at 12V and about 2 amps. when i put a screwdriver in the coil, the current ramps up to about 3 amps and the screwdriver gets hot

Yes, but you may need to use logic level MOSFETs or at least ones with a low gate threshold voltage.

Would it be possible to scale this type of circuit so that it could run off of a small Li battery (say 10V, 1A)? I’m interested in heating something with roughly the mass of a penny to no more than 200C.

Rob, You need a good quality soldering iron and clean copper. heat the copper up and get solder to stick to that first.

Andrew, No, it wont supply enough power.

Brad, Higher input voltage for more power.

I have a working coil that is 130mm DIA, wanting to heat a steel ring ID:115mm, OD:125mm, thickness:1mm. I would like to be able to heat the ring to 100c from room temp as fast as possible (5-6 sec). Currently, I have built the circuit using the same components as detailed, the heat is there, but it is taking around 45-50 seconds. I have the mosfets running from a 12V PSU and the coil is running on 22V at about 7A. Do you have any ideas or recommendations that might help this get closer to the speeds I am trying to achieve or steer me in the right direction? Brad.

Is it safe to use a 5V power supply and an LM2577 5V to 12V DC Converter step up Voltage Regulator instead of the 12V 30A 360W power supply?

I’m having trouble soldering the capacitor bank to the coil. Do you have any suggestions?

Hi Simon and brenden thanks for u r reply I have changed new values as u advised that’s works great thanks u guys very big thanks to father of this project rmc .

Dear Rmcybernetics,

Can you please shotly explain me the working principle of the circuit. The induction and Eddy current is ok, but I really don’t understand the switching method. Why are the MOSFETs switching permanently one after another. There is no control signal or anything. I know, it is very simple, but I don’t know how it works.

Thank you very much!

I’m currently using the CRO-1 and one of the ready-made work coils to heat some brass casing. The coil, however, is a bit on the big side since I only need to heat the top 10 mm of the brass casing. This results in a very inefficient heating. I’ve tried to make smaller work coils while increasing the capacity to keep the resonance frequency fairly the same. It worked to a degree, until I got overconfident and made the coil too small and killed the transistors (whoops..).

Now I ordered the matching transformer kit, and i’m going to experiment a bit more with this. I’d love some pointers on how to wire things up as a start.

I’m initially thinking about having 10 windings on the primary side, and maybe 4-5 on the secondary side. The work coil would need to have as little as 3 windings to be optimal. How much capacitance would i need for this? Would i need to tune the LC tank to about 100 kHz?

great article. trying to build this circuit, however the only thing that’s heating up is R1 & R2. any ideas why this would be?

Hi there! nobody clarifies that so i thought i could ask. You sell a 1kv cap, by the size i can tell for sure is not rated as 1kv DC 1kvdc high frequency caps are at least 2-2.5 inches with allot bigger leads and costs at least 10$ each so what is it rated? And what a good rating for a single cap would be so he would not be heated with your specified components and with lets say a 30v 15 amp psu?

Thanks rmcybernetics! great project!

hi branden thanks for u r reply can u please help me output rectifier and filter circuit for this.i am using 24 volts 15 amps toriodal transformer.

Great article and a great device.

I have built one of these and it works OK with my 2 inch water cooled coil.

I would love to adapt this to a small are so I can anneal small brass. A Flux concentrator looks like a great option but have never used this type of setup before. has anyone got any ideas on these and were I can purchase them from?

Brandon, none of those caps are suitable. You need good quality polypropelene capacitors or an equivalent. The voltage rating must be at least 200V, ideally 400V or more. Capacitance needs to be 1uF or more.

Balaji, Your transformer setup is not suitable. You will need a more stable DC supply. The filter capacitor is way to small to accomdate the current demand.

i am using 24volt 15 amps toriodal transformer 15amp bridfe rectifier and filter capacitor 4700uf 60volt after 7824 and 7812 regulator to 220E 1watt resistor stp30nf10 FET 5822 shottky diode LC 1mH inductor 330nF 275 ac cap my coil is pretty large after connecting i am getting small amount of heat FET is getting burnt after few seconds.capacitor value is ok FET i have to increase volt rating or current rating.

What’s more important? The voltage of the capacitor, the sive, or the capacitance.

Quick question. Which cap is better. One from a PC power supply at 330 uf and 200wv,or one out of a microwave at 0.75uf +- 3% 50/60 Hz with 2100v ac. The microwave cap is large I’d say 3in x2.5inx1.5in. Standing up right it would be HLW. The cap from the PC power supply is a cap about the size of the first notch of my thumb. In other words, what I’m asking is: is size, voltage, or uf more important?

The wires should be insulated otherwise they will just short when touching. The regulator can help give a more stable supply voltage to the transistor gates.

When talking about the toroid, is it okay for the wires that are wound around it to be uninsolated, and also touching? Also, this question might be as obvious as I think but, what is the regulator? I see that some schematics have it and some don’t.

2kW is not going to be so easy. We will do another project for more power, but I can not really give any suggestions at this time.

Hi, I’ve been reading about induction heaters for a while and this is by far the most helpful page I have come across yet. I’m looking into induction heating as a solution for a problem I have with my PhD project. I need to heat a 4" hollow SS cylinder 20" with refractory material inside. My calculations show that I need 2KW of heat. I’m assuming I need a bigger setup than the one you have here. In your expert opinion, is it easy to build a heater for my setup? I have attached a PDF of the setup so you can have an idea of the size of the setup (I only need to heat the part highlighted in red)

Ahh can’t make it to work. I used 330ohm resistors instead of 240, plus the 7812 to feed the gates.

Used a 7uH~ coil with center tap (7uH total). 310nF divided into 5 capacitors, what would give around 108KHz. But all it does it blow the fets.

I read that a big ferrite inductor would not be a problem, so I started with 8mH, but since I already blow 2 fets, I won’t test again before I realize what is going on.

I used a MOT winded to give me 16,8V on a 25amp bridge and a 6800uF capacitor.

I tried this method but found it would sometimes fail to resonate properly so went with this method instead. It may well work ok with a bit more tweaking.

I have been a home constructor for many years but am fairly new to power mosfet ccts. I have seen other designs based around the mazilli ZVS driver using 2 chokes to feed the drains either side of the work coil thus precluding the need for a centre-tap. Do you forsee any pro’s/con’s for this arrangement.

karan, for non-ferrous metals you will need to to higher frequencies and power levels. This little curcuit will struggle with that.

heaterhotter, No dont use these capacitors, they are not meant for use in this way.

Hi

This seems like a great simple project and I am just getting together the parts now.

1 question about capacitor type, would a microwave capacitor be safe to use in this circuit? They are rated for high frequency and 1000 to 2000v .8uf to .98uf

One example I have is measuring 0.977uf with an esr of 0.7257 ohms, is that considered a low enough esr for this circuit?

My biggest fear is overheating this metal can capacitor that is filled with oil and blowing it up, burns, a mess, bad memories, things to avoid 🙂

Hi rmcybernetics

Thank for your explain in DIY induction heater. I am follow your advices ,everything is perfect.

I would like to know , If I would like to heat with non-ferrous like aluminum,silver,…Do you have any products that suitable for this case or Any products can heat more than curies temperature ?

Thank in advance.

I built the circuit and it works well, but instead of the 240Ohms i used 20Ohms, what reduced the mosfets temp. I use these Mosfets

http://www.vishay.com/docs/91482/sihg73n60e.pdf (600V, 70A). The Choke used is a inductor from coilcraft with 22uH and ~2mOhms resistance. The problem i have is that the device does not heat above slight red, and i want at least to reach curie temperature. I tried to use a 10uF pulse capacitor but the coil gets hotter than the workpiece (10AWG!!!!!!!!). Another problem ist that i cant measure the frequency, beacause the multimeter dies, if connected to the coil, and on the gate it measures (probably wrong) 4MHz. (Heater coil: 5+5 10AWG, capacitor: 5*0.1u MKP or 10uF Pulse Capacitor). Does someone have useful tips?

I answered my own question by reading the "pushing it further portion on the cap configuration. Multiplying caps in parallel increases total capacitance. Cheers.

Thanks a lot RM Cybernetics,

When you say "add more parallel capacitance", do you mean larger value capacitors? or more of them?

I get the "current sharing" effect….

it is my understanding the resonant frequency is determined by the relationship of the capacitance rating and the work coil inductance….

….so, larger value caps and then work out the current sharing by adding more of them to reduce capacitor heating where needed?

YOU’RE AWESOME!!!!

Brian, Diodes might be failing because of voltage spikes or because of losses at high frequency (Frequency is higer with fewer turns). Try adding more parlle cpacitance to bring down the frequency to allow for more current.

Rob, Use a bigger choke to limit the current or more turns on the work coil.

Ok, Thanks RM Cybernetics!

I have successfully built a heater with:

12v 30A led psu hooked to 12+/12-

Choke is 14 turns #16 magnet wire on 20mm powder core

4+4 of #14 magnet wire

Caps are .68uF (using between 3-7 at a time in an attempt to increase current flow with seemingly no effect on heating)

Irfp260n mosfets

1kv 4007 diodes as suggested

240 Ohm 1/2 watt resistors

I did use an open loop copper attenuater as noted prior (I cut it along its length so it’s not a closed turn)

I have gotten it to heat up pretty hot but would like to push it a bit more.

I attempted to take turns off the coil down to 2+2 (burned diodes?) and back up to 3+3 (diodes safe) but no more resulting heat than I had before.

I then reduced my choke turns to as low as 8 before it fried my switches and back up to 12 turns to avoid failure.

I have not been able to reach curie yet.

Question: Is there a balance to be struck between turns on the choke and turns in the work coil in order to increase current? It seems my PSU is sufficient…..something is telling me I need to, somehow, "open the flood gates".

Thanks (a lot) in advance,

Brian

I am interested in building this circuit with a lower operation power. I would like to heat a ferromagnetic rod, lets call it a nail, to around 200 C and stabilize it at that temperature using a feedback loop. Is it possible to use mosfets with lower current ratings and a smaller capacitor bank in order to reach this lower temperature? Heating it to red hot is cool but not necessary.

So, I’ve built a functioning unit in my cylindrical design. It variably heats up different sized loads but not quickly, and not to curie temp.

The high points:

12v 30A power supply fed from 12v+(line)/12v-(ground)

Work coil is #16 magnet wire, turns=4+4, wrapped on a glass bobbin and inside a copper attenuater with an open circumference.

Choke- 8a, 100uF prefab (about 3/4")

Caps- 3 each 1000v .68uF polypropylene

Diodes are 4007’s 1000v

Resistors are 240ohm 1/2w carbon film

Mosfets are irfp260

I attempted to change the coil to 3 turns of #14 bare wire (no shorted turns) and removed the attenuater and a diode popped. I rebuilt the prior coil, replaced the diodes and it functioned again.

Do you think the un-attenuated EMF destroyed the diode?

Thoughts on beefing it up to get to curie temp?

THANKS!

Nice work Roberto. Ian, You will probably need more than a 10x probe to be sure of keeping your scope safe from voltage spikes. Put the eath clip to the batter negative terminal and then you can measure the waveform on either side of the coil. What you will see is one hald of the resonant sine wave form.

Hi RMC

I have made a couple of heaters – Both work fine & I’m slowly moving towards higher power to give quicker heating of my work pieces.

I wish to use my USB oscilloscope & PC to see the wave forms around the circuit & check frequency etc

Can you advise me where to connect the earth clip on my probe to on the circuit so I don’t fry my scope?

Should I use a x100 probe (when I’ve made one) so that I stay safe? or will standard x10 be ok – my power supply is 24V DC (battery)My first circuit oscillated at 230KHz and draws 16 amps.

Brian, The copper sleeve might act like a shorted turn if it is in close proximity to the coil. It would be better to have it split into isolated sections to reduce eddy currents.

Brandon, thanks for sharing your project. Congratulations!

Hi

I took a picture of the circtui working and I wanted to share.

Thank you for sharing this project.

I feeded it with a little bit more current and managed to get a nail red hot in aprox 90 seconds.

Some curiosities if you see my project post #5246 you will see I used aligator clips to conect the main coil to the circuit. Later I read in the article that these conections sjhould be short and with good diameter copper wire. Well mine just were too thin. Thinks go ok when I place ferrous material inside the coil, but if I place aluminum or copper the plastic in the aligator clips start to melt and the aluminum piece of the copper does not get hot. I did see on youtube an induction heater melting aluminum so I thought mine would do this as well.

Working current is now aprox 5,25 when getting the nail red hot.

Hi, I was able to get my circuit working reliably and was able to get a knife red hot in about 15 seconds. I used all of the components you used including zener diodes between the source and drain for protection. My main issue I think was my torroid core inductor that I wound myself. Not really sure what was the issue with it, but I made a new one and now it works like a charm. Thank you for the article!

Wow, I’ve been studying this project for six months. Thank you to everyone involved.

I am developing an innovation on this and wonder about the effects of the work coil on the other components.

As you can see my design is cylindrical with the circuit wrapped around the coil, outside of an insulated copper sleeve meant to act as a magnetic planewave attenuater with the purpose of redirecting the flux away from the rest of the circuit and back through the middle of the work coil.

Questions:

1. Is it practical to attempt a build with such small tolerances or will the flux interfere with the driver, prohibiting it from operating?

2. If planewave attenuation is realistic; would the sleeve itself need to be grounded, isolated, biased?

Thanks in advance,

Brian

Brandon, Roberto, Unfortunately I cannot comment on every different version and different transistor/capacitor etc. Pretty much everything that I can say about getting this project working has been said either in the article or comments already. Have a good read through and you should get really valuable information from the posts of others working on the project too.

Hi this is my second post. Picures of my induction heater have benn posted on first post.

Today I managed to make it work.

Basically I changed the power supply from a 12 v 7 ah batt to a 24 v 2A transformer (able to deliver up to 4A aprox). With this setup I managed to see my induction heater heating up a small nail. It did not get red hot but was hot enought to vaporize water. Thank you for sharing this nice project.

I did try with a smaller diameter coil but that did not make the heat more powerfull. Is there any thing besides higher current and voltage that can make it heat up more ?

Tks

Roberto

Hi I am building your induction heater project

I used

2 capac de 224k

2 mosfet IRF540N

(option to use W40N20 mosfet)

coil 8 turnes enameled copper 12 awg

Batt 12v 7ah

current consumption when powered up 2,24 to 2,44 A

A picture of it is here

https://dl.dropboxusercontent.com/u/21484405/induction%20heater.JPG

I know I am using too little power but I was expecting at least a minimal heating of a small metalic (ferrous) piece I placed inside the coil.

I do not have an oscilloscope, can you give me some suggestions to see it working ?

Perhaps a smaller coil, or perhaps change the mosfet to the W40N20 or just rise the input voltage. Also change the capp bank perhaps. Any hint would be very welcome. Tks for sharing this interesting project.

Hi, I got the induction heater working at one point, but my capacitors started smoking and now they bulge a little bit at the sides. This was after running it for about 3 minutes. I used the same capacitors that are used in the article. Anyways, so I replaced them with Mylar capacitors, would this be okay?

Also, one of my MOSETS burned up so I found these IRFPS3810 but it doesn’t seem to be working, one of MOSFETs gets really hot and starts smoking. Maybe they are too slow?

Here is a video sent to us by Doug. Here he shows an example of using a pancake coil.

Here’s a picture of the physical circuit

Hey so I’ve read this article probably a hundred times these past few weeks and I’ve been super excited to put one of these together. I’m having a bit of a problem though. One of my irf540’s will overheat and smoke almost as soon as i turn it on. The choke I used was orginally 61mH and i took about 2 winds off. I measured my coil at school to be about .2mH which I removed another turn and a half from. The caps are .1uf 1000v. At first I didnt have the lm781t or the 1n4740a but I had them and saw another schematic using it so I figured it wouldn’t hurt. I originally tried the driver circuit exactly as the article on my breadboard and i got the smoke so I added the extra components and put it on a perf board to no avail. Its probably worth noting also its only one MOFSET that gets super hot and the other does nothing. Not sure if I wired something wrong or If Im doing something toatally wrong or whats the deal but any help would be awesome. P.S its being run off a 500w psu with the 12v rail at about 10A. The first one I used went to protect the second one caused the heat problems,

1. No, but it might be useful to watch your DC input to ensure it never drops below 12V.

2. It would need to be huge. Google for PSU capacitor calculations for details.

3. Yes you can parallel more capacitors onto it which will reduce the operating frequency.

I just received your power and coil modules to try. A couple of questions. (1) No scope; can I be sure the voltage for the MOSFETs is under 100v by watching the DC voltage input to the power module? I’ll put a variac on the transformer input. (2) How much capacitance is good on my power supply DC output? (3) I have capacitors from induction cookers that should be suitable (I think) – OK to parallel some of those across the coil to double the capacitance (will that half the frequency)?

Thanks for a great-sounding and -looking product and thanks for the help. Oh, the reddish cup near the coil is from a TIG welding torch and I plan to put it inside the coil as electrical insulation against shorting out from the piece I’m heating. The transformer weighs over 4.5kg so I think it will supply good current.

What is the maximum temperature that can be obtained with this heater? Assume the material to be heated is thin copper wire, variable quantities. What can be adjusted (besides power) to tune the heater for this. How can I achieve the optimal setup for maximum temperature?

David, it’s easy to melt copper with a good inductive heater, provided you’re putting out enough magnetism. One thing to note is magnetic field strength of a coil is dependent on current and not voltage (B = (material permeability) * (current) * ([number of turns] / [coil inductance])). You could have 5 volts or 50 volts at 5A and the field strength will be the same for both voltage levels. If you really want to dump some good heat into the copper to make it melt, up your current through your primary work coil. If you’re worried about power supply wattage ratings, use a transformer to get your voltage down from 24V to 6V (or whatever your incoming is down to as low a voltage as you can safely switch). Just in this example, you’ll quadruple your current (P = V * I) which will in turn give you more to work with. In any case, it’s the current you’ll want to modulate and not your voltage. Give yourself enough voltage to make your circuit work (drive MOSFETs and such) and let your current do it’s thing.

I plan to use the induction heater for melting small amounts of copper. I hope to reach the required temperature. The copper I’m talking about is small diameter wire 0.1 to 1 mm. I plan to use a DC power supply that can be adjusted between 0 and 30 V and is current limited to 5A. I would only be melting small amounts at a time. Tens of grams to maybe 100 grams max. Do you think the induction heater will get the material to the required temperature. Copper melts at just above 1000 degrees C.

I plan to buy a built model from the shop to ensure best quality build.

I want to use this device to obtain hot water. The water pipe that will be into the coil must be from copper or steel?thanks! adrian

Just curious on your capacitor arrangement on this one. I think the reason your capacitors are getting hot is because of how they’re wired into the circuit. Normally a capacitor being used as a resonance component is wired in series or parallel with the inductor(s) they’re meant to resonate against. In this circuit, we have two main coils (the primary is split in half at the center tap and is essentially two coils placed on top of each other) and only one capacitor. In order to get each coil half to resonate, the capacitor should be hooked from the positive side of the primary work coil to ground. This puts it in true parallel with the inductor it’s resonating against and will cause actual resonance to occur.

In other induction heaters I’ve seen/built, the main work coil has been a single piece driven in AC by either an actual AC source or a high powered, complex inverter that provided the signal and was tuned to the resonance. The main inductor was bridged by the capacitor so that there was always a high and low voltage reference point. When the waveform flipped, so would the voltage levels across the capacitor and inductor. In this design, the capacitor is essentially connected to a ground and an open terminal. When the waveform switches, the capacitor switches it’s ground pin and open pin. I’m somewhat surprised this circuit resonates at all, let alone does what it does without burning up in the process.

I built the circuit here with the only modification being that I used two capacitors instead of one. Each capacitor went from the center tap of the primary work coil to its respective mosfet drain (so connected one side of each between L2 and L1 and then ran each to a mosfet drain). I powered up the circuit and ran it for several minutes (5-10) with no adverse effects. I was even using mylar capacitors and ran my mosfets using 1k resistors. I couldn’t make it not resonate. I even used the first diodes I came across (ended up being Zener) and it still resonated.

So all the people having trouble with this, I would suggest trying to put your caps in parallel with each half of the work coil. Like I said, I had "junky" parts (stuff that has been deemed here as not fast/powerful/responsive enough to run) and I couldn’t make it not run. Provided you have the power supply (can’t make miracles with that), this thing will hum right along, adjusting itself like it’s said to and working just fine.

Connecting the Litz Wire like this is fine.

Is it possible to connect a 20 amp Litz wire to the induction heater by soldering a single wire from the inductor to the middle of the winding of the litz wire like on a non litz wire(copper cable)?

or would that short the wire out thanks.

Higher input voltage and therefore more current.

Good morning, I have a doubt, if I wanted to increase the magnetic field (up to 90 Gauss at least) keeping the resonance frequency = 100kHz, which should change? Features that can be used: coil wire diameter 4 mm, total length 1m, 6 capacitors of 0.33 uF each, resonance frequency (shown on the oscilloscope) fo = 100 kHz, with this the indutancia of indutor 1.27uH , tension between the capacitors = voltage in the coil(indutor) = V_entrada = 41 V (peak to peak 82 on the oscilloscope), doing some calculations:

Z_equiv = sqrt ((Rl ^ 2 + (Wo * L) ^ 2) / ((1-C * L * Wo ^ 2) ^ 2 + (C * Rl * Wo) ^ 2));

I_entrada = V_entrada / Z_equiv;

I_entrada Iindutor = / (C * Wo * Rl) Rl: resistance inductor

obtaining the current in the inductor (coil) of 49A and using this in the simulation program Opera 3-D get a maximum magnetic field of 40 gauss

(Adjunt photo )

Jed, No. High current is needed to make a strong magnetic field in order to induce current in the metal workpiece. Higher frequency will heat smaller items and heat the surface more quickly due to skin effect. At higher frequencies the transistors will be less efficient however due to parasitic losses.

by the way, kindly explain to me the resonant frequency? would it be good if its lower or higher? Because I have a two toroid inductor with differents sizes and planning to connect it on series to increase the inductance to lower the resonant frequency. What would be the effect of lower resonant frequency in the circuit and vice versa?

hey, can I use a low current power supply? like a 250mA transformer combined with a bridge rectifier. Why do we need high current?

Bud, Energy savings from induction cooker tops are becasue only the pan is heated and less heat is wasted by heating the air around it.

ridwan, You need to put a choke in it. Other than that I can only assume you have not built as described, or some of your parts are faulty.

Man, thanks for that super useful and simple design!

I built the circuit as you recommended and I got it oscillating. but the problem is using 15v power supply, I am getting a sine wave with just around 2v peak-to-peak. And the second problem is teh circuit is not drawing any current. some 20mA is flowing through the gate resistors, but none through the coil. by the way I built the circuit with out chocke and it is actually oscillating at very low amplitude as I just pointed out above.

I would love to have as much heating capacity as yours. my supply is 30V,10A.

new person here, stumbled into this area looking for info about induction heating. interesting stuff. i will try to keep it short but need to share a little so whomever replies will understand what started this for me, I knew a little about induction heating, saw and ad on tv for the little counter top induction cook top (nuWave) bought one, they claim 70% less power to cook something over resistance type stoves. SOooo my idea was , why not use a cleverly designed induction heating element to replace the resistance type element in a water heater? here is were my web search began , now I’m here, any comments or ideas , water heating is a big part of a households consumption , 70% less (or even 30-40%) would seem like a good idea. I then heard that the "on-demand" water heaters were induction heated, is this true? comments , info, ideas…..?

like this? ok I’ll try to ask my mates to make up their mind. Happy New Year.

No. Load -ve should go to GND on the heater circuit. Distance is not a problem as we can deliver our products worldwide.

you mean like this connection in the picture?

do you think I can still control its temperature using that circuit?

Please give me a picture of where I can connect it in order to combined this two. Please. It will be very helpful for me to understand this. I usually want to buy your devices but your place is too far away. 🙁

Not really the best way to do it, but you can just connect up the induction heater power terminals as if it is the load on the other circuit. You will need to keep the PWM frequency very low though otherwise the resonator may not get chance to start up between pulses.

Can you please tell me where I can connect the Pulse Generator output (Two RED dots) to the induction heater circuit as shown in the picture?

If the two combined, do i need to supply 15V DC to the induction heater circuit or the Power pulse generator will supply it. Thanks for answering.

Do you think this will work if I follow all the ratings of your given circuits?

Michel, As mentioned in the article, you can not use most IGBTs due to them having a large voltage drop.

Hazem, you really need the capacitor which unfortunately limits the frequency. The resonating coil/capacitor allows for a much stronger current flow in the coil. You would perhaps need to make a set of different resonators to try out each frequency.

Hello, I am pretty much a noobie regarding the topic but I need to setup up an induction heater coil to heat up an oil sample for my thesis. What I have done so for is connect a variable frequency EM generator to an amplifier and finally to a copper coil. What I was hoping to do is to see how the heating changes as I change the frequency, however I barely got any heating until I put a capacitor in parallel which eventually burned. Is there a way to make a setup where I can still use the generator to vary the frequency as I want or would the frequency still solely depend on the capacitance and inductance of the coil?

Hi I need to do the same proyect but using IGBTs Do I just need to change the MOSFETs for IGBTs using the same configuration????

Thanks

Jeff, You need to connect DIS to GND to activate the circuit.

Lasse, You should always add a capacitor between the output of a voltage regulator and GND as this helps keep the output stable. Value is not critical, but something around 330uF is fine.

Hi, I cannot get my circuit to oscillate after putting a regulator in there, like in a post #4649. I figured that I need a condensator after the 7812 regulator and probably before too. I was wondering how large condensator should I use?

Just purchased the induction heater driver circuit and can’t seem to get it working.

I made my own coil out of 1/8 copper pipe that measures out to 1.49 MicroH. I am using 2 .22 HF MicroF caps for a total of .44 . This calculates out to 198K Feq. For the power supply I am using an Omron s8ps-30024cd – 24V 14A Power supply and have it set at 22.2V output at this time.

The board LED and fan powers up, but no output at the coil and only milliamps draw from the supply.

What am I missing?

Use two types of choke, to know what was the best, the first of 19 turns (12 AWG), and the second of 10 turns (14 AWG). It turned out that the best was the 19 laps, 19 turns the choke warmed faster than 10 turns.

Do not know if my problem is the capacitors that are very small (.01 uF x 10) or my choke. My work coil are 8 laps, use 14 gauge wire.

The power supply is a simple 12-volt battery.

The 240 ohm resstors limit the current to a maximum of 50mA per transistor. The actual current will vary depending on operating frequency.

Hi, I was wondering how much current the mosfets draw from the 7812 regulator?

Brad, No. There are actually a lot of variables that will determine the workpeice temperaure so I can not really help with that.

Hi,I have a problem with my induction heater, and it takes a long time to heat the piece

The components are

L1 = aprox 2mH I’m not sure

L2 = I don’t know (8 turns, 12 awg wire)

Power supply, battery of 12v

mosfet 30nf10fp

diode 1n4007

resistors 220ohms

capacitors 10x.01uF 1600v

Do you have any tables or data on what equivalent temperature if you produce a value of power? I mean if you produce 300 watts, what will be the temperature of the metal inside the induction coil?

Brad, Yes you can but you will need to use our Impedance Matching Transformer Kit as it will let you drive a single coil winding and will allow for better power transfer.