Static Electricity Motor

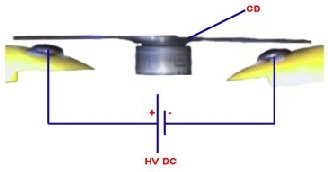

A CD with one side covered in foil can be made to spin at high speed by using static electricity, or high voltage DC. With the CD on a spindle with the foil side up, areas under the CD can be charged by nearby electrodes. If the electrodes are placed either side of the CD and just underneath it, charge will be deposited on the plastic surface of the disk.

The plastic disc is non conductive, so in order for the charge to get to the other electrode (of opposite polarity), the disk its self must turn. This physical transportation of charge still constitutes a current flow, even though the current does not flow within the material itself. The flowing current is directly proportional to the speed of the rotating disc.

The plastic disc is non conductive, so in order for the charge to get to the other electrode (of opposite polarity), the disk its self must turn. This physical transportation of charge still constitutes a current flow, even though the current does not flow within the material itself. The flowing current is directly proportional to the speed of the rotating disc.

I did try the device attached to my Zamboni battery. You were right, it could not overcome friction. My Zamboni batteries output was closer to 500V. I thought it would be higher, but I am still working on it.

1kV might be a bit too low to get enough force to overcome the friction. If you try it, let us know your result.

Will this motor work at 1KV? I have made a Zamboni type battery. It puts out around 1KV, do you think this would power a motor sucha as you described?

Here is a picture of the motor I made, built as per previous post.

By adjustment of electrodes, it will spin from a slow crawl to a few hundred RPM’s.

Actually no foil is needed. A regular CD is all you need. Works fine for me with a 7KV negetive ion generator module. Turns about 70 RPM.

For a suitable bearing system – use a ball bearing muffin fan, take it apart and remove the round rubber magnet and snip away the frame and the blades, reassemble. Set or glue the CD to the part that had the blades. The motors in CD drives were tried but they are made with sleeve bearings causing too much friction.

Works much nicer than the plans you see on the net using motors made with plastic pop bottles or plastic cups.

Have fun, enjoy

The foil on the top is one single piece covering the whole surface. It is best to leave a small gap so that the foil does not go right up to the edge of the CD. About 5mm should be fine.

The voltage required will depend on a few factors such as the size and shape of the electrodes, and the distance they are from the CD surface.

The voltage used on this vesion was around 10kV, but lower voltages should also work. There just needs to be sufficient voltage for a strong enough electrostatic attraction to move the CD. At lower voltages it may be necessary to give it a nudge (with a plastic rod) to get it spinning.

Once it is spinning it will continue to accelerate until it is drawing as much current as your PSU can supply or friction becomes too significant.

I couple of questions:

First, the foil on the top is it sectioned or completely covered?

Second, how much voltage is needed to run the motor?

Thanks